9.1. Information on Basic Physical and Chemical Properties

Section 9.1 of the Safety Data Sheet (SDS) provides essential information on the basic physical and chemical properties of a substance or mixture. This information is crucial for hazard assessment, safe handling, storage, and transportation. It also supports proper emergency response planning and environmental impact evaluation.

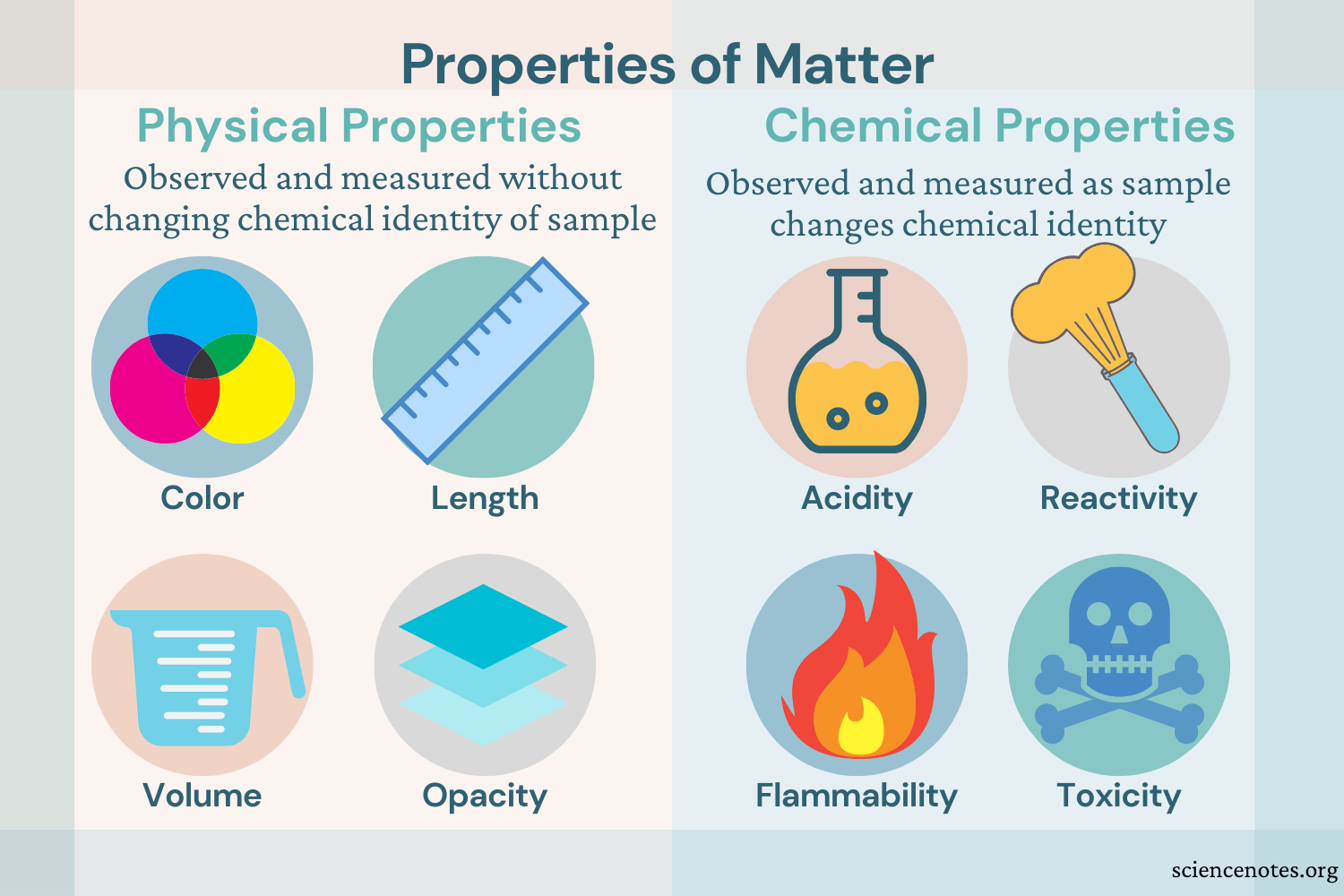

Physical Properties

Physical properties describe characteristics that can be observed or measured without changing the chemical composition of the substance.

- Physical State: Liquid

- Color: Colorless to pale yellow

- Odor: Characteristic

- Appearance: Clear, transparent liquid

Chemical Properties

Chemical properties describe how a substance interacts with other substances or changes under certain conditions.

- pH: 6.5-7.5 (20°C)

- Melting Point: -5°C

- Boiling Point: 180°C

- Flash Point: 65°C (closed cup)

Safety-Related Properties

These properties are particularly important for hazard assessment and safety considerations.

- Flammability: Flammable liquid

- Explosive Properties: Not explosive

- Oxidizing Properties: Not oxidizing

- Vapor Pressure: 2.3 kPa at 20°C

Additional Properties

These properties provide further information about the substance's behavior and characteristics.

- Relative Density: 0.95 g/cm³ at 20°C

- Solubility in Water: Miscible

- Partition Coefficient: Log Pow = 2.4

- Auto-ignition Temperature: 235°C

Importance for Hazard Classification

Many physical and chemical properties directly determine hazard classifications under GHS and other regulatory frameworks:

- Flash point and boiling point determine flammable liquid categories

- Physical state affects exposure routes and hazard communication requirements

- Explosive and oxidizing properties determine specific hazard classifications

- Partition coefficient influences bioaccumulation potential and environmental hazard classification

- pH extremes may trigger corrosivity classifications

Regulatory Requirements

According to GHS and various regional regulations (EU CLP, US OSHA HazCom, etc.), Section 9.1 must include all relevant physical and chemical properties. Key regulatory considerations include:

- EU REACH Regulation 2020/878 requires specific properties to be listed with appropriate units and test methods

- US OSHA Hazard Communication Standard (29 CFR 1910.1200) mandates inclusion of all relevant physical and chemical properties

- Transport regulations (ADR, IMDG, IATA) rely on physical properties for proper classification

- Properties must be determined using standardized test methods where applicable

- When properties are not applicable or data is not available, this must be clearly stated with justification

Test Methods and Standards

Physical and chemical properties should be determined using recognized test methods. Common standards include:

- OECD Test Guidelines: Internationally accepted methods for determining properties

- EU Test Methods: As described in Regulation (EC) No 440/2008

- ASTM Standards: American Society for Testing and Materials methods

- ISO Standards: International Organization for Standardization methods

- UN Manual of Tests and Criteria: For properties related to transport of dangerous goods

When reporting properties, the test method should be indicated where relevant, especially for properties that can be determined by multiple methods (e.g., flash point).

Example of Complete Section 9.1 Entry

| Property | Value | Method/Conditions |

|---|---|---|

| Physical state | Liquid | at 20°C and 101.3 kPa |

| Color | Colorless to pale yellow | Visual assessment |

| Odor | Characteristic | Olfactory assessment |

| Melting point/freezing point | -5°C | OECD 102 |

| Boiling point | 180°C | ASTM D1120 |

| Flammability | Flammable liquid | Based on flash point |

| Lower and upper explosion limit | 1.5% - 8.0% (v/v) | Literature data |

| Flash point | 65°C | Closed cup, ASTM D56 |

| Auto-ignition temperature | 235°C | ASTM E659 |

| Decomposition temperature | >300°C | DSC analysis |

| pH | 6.5-7.5 | at 20°C, 100 g/L in water |

| Kinematic viscosity | 15.8 mm²/s | at 20°C, ASTM D445 |

| Solubility | Miscible with water | at 20°C |

| Partition coefficient n-octanol/water | log Pow = 2.4 | OECD 107, at 20°C |

| Vapor pressure | 2.3 kPa | at 20°C, OECD 104 |

| Density | 0.95 g/cm³ | at 20°C, ASTM D4052 |

| Relative vapor density | 3.5 | (air = 1), calculated |

| Particle characteristics | Not applicable | Substance is a liquid |

Quality Assurance Checklist for Section 9.1

- All relevant properties are included with appropriate units

- Test methods or standards are specified where applicable

- Temperature and pressure conditions are specified for relevant properties

- "Not applicable" or "Not available" is used with justification where appropriate

- Values are consistent with hazard classifications in Section 2

- Properties are reported using appropriate significant figures

- Information is consistent with other sections of the SDS

- Ranges are provided where appropriate (e.g., for mixtures)

Best Practices

When preparing Section 9.1 of an SDS:

- Use standardized test methods and clearly indicate which methods were used

- Ensure all mandatory properties are included according to applicable regulations

- Provide values in SI units with appropriate conversions if needed

- Specify test conditions (temperature, pressure) for all measurements

- Ensure consistency between physical/chemical properties and hazard classifications

- Update property data when formulations change or new test data becomes available

- Include property information relevant to safe use and handling, even if not explicitly required

Note: Values are typical and may vary slightly between batches. Specific technical specifications should be consulted for precise values. The properties listed above are for illustrative purposes and should be replaced with actual data for the specific substance or mixture.